Back to Course List

Plastics: Intelligent Molder, Program 3: Process Evaluation

- Product ID

- arasim03

- Training Time ?

- 64 to 128 minutes

- Language(s)

- English

- Video Format

- Standard Definition

- Required Plugins

- MasteryNet Player

- Lesson Interactions

- 63

- Quiz Questions

- 43

Overview

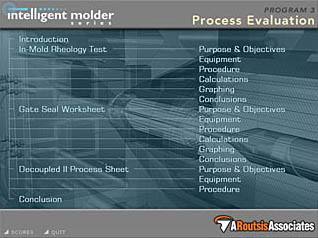

This three part training series refers to three in-depth tests used to assess the accuracy and repeatability of an injection molding process. The three tests covered in Program Three are: The In-Mold Rheology Test, The Gate Seal Worksheet, and The DECOUPLED II Process Sheet.

![]() This course is in the Advantage™ format, to read about Advantage™ features click here.

This course is in the Advantage™ format, to read about Advantage™ features click here.

- Rich multimedia presentation with interactions and quiz

- Print certificate and wallet card

- You have 30 days to complete the course

Workplaces

Audience

For technicians and process engineers working within the plastics industry who want to thoroughly evaluate both the capability and repeatability of a given injection molding machine, injection mold, or injection molding process.

Topics

The course presents the following topical areas:

- Introduction

- In-Mold Rheology Test: Purpose/Objectives

- In-Mold Rheology Test: Equipment

- In-Mold Rheology Test: Procedure

- In-Mold Rheology Test: Calculations

- In-Mold Rheology Test: Graphing

- In-Mold Rheology Test: Conclusions

- Gate Seal Worksheet: Purpose/Objectives

- Gate Seal Worksheet: Equipment

- Gate Seal Worksheet: Procedure

- Gate Seal Worksheet: Calculations

- Gate Seal Worksheet: Graphing

- Gate Seal Worksheet: Conclusions

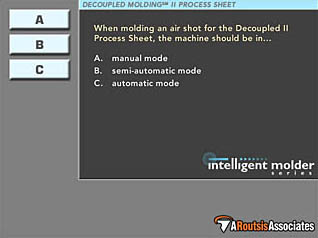

- DECOUPLED II Process Sheet: Purpose/Objectives

- DECOUPLED II Process Sheet: Equipment

- DECOUPLED II Process Sheet: Procedure

Intended Performance Outcomes

Upon successful completion of this course you will be better prepared to:

- Know how to achieve a 'robust' injection molding process of any machine.

- Understand why and how to determine the optimal filling rate.

- Identify which pieces of equipment are required for the In-Mold Rheology Test.

- Use procedures to properly perform the In-Mold Rheology Test.

- Follow the steps involved for calculating the In-Mold Rheology Test.

- Properly graph the results of the In-Mold Rheology Test.

- Know how to proceed after calculating the recommended 1st Stage Fill Time.

- Understand why and how to determine an adequate 2nd Stage Time.

- Use the required pieces of equipment for the Gate Seal Worksheet.

- Properly perform the Gate Seal Worksheet.

- Calculate the Gate Seal Worksheet.

- Properly graph the results of the Gate Seal Worksheet.

- Follow proper procedure after calculating the 2nd Stage Time.

- Understand why and how to determine a standardized setup sheet for each mold.

- Use the required equipment for the DECOUPLED II Process Sheet.

- Follow procedures to properly perform the DECOUPLED II Process Sheet.

© Mastery Technologies, Inc.