Plastics: Math for Molders: Program 2

- Product ID

- arasmfm2

- Training Time ?

- 89 to 178 minutes

- Language(s)

- English

- Video Format

- Standard Definition

- Required Plugins

- MasteryNet Player

- Lesson Interactions

- 85

- Quiz Questions

- 66

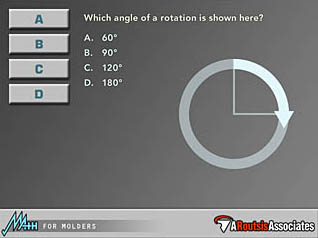

This training, the second in a two-part series, ensures math skills needed for the injection molding worker. Mathematics is used throughout the injection molding industry on a daily basis in many different capacities. It can be as simple as counting inventory or as complex as calculating the tonnage required for a multi-cavity mold.

Math skills are required to perform common tasks like calculating part tolerances, determining production requirements, or comparing measurements. They are critical when performing advanced functions, such as; intensification ratio calculations and converting hydraulic pressure to plastic pressure - all of which are covered within this two part training program.

![]() This course is in the Advantage™ format, to read about Advantage™ features click here.

This course is in the Advantage™ format, to read about Advantage™ features click here.

- Rich multimedia presentation with interactions and quiz

- Print certificate and wallet card

- You have 30 days to complete the course

For all personnel in the injection molding industry that would like to expand or fine tune their math skills. These courses will greatly benefit any participant of RJG's classroom-based, Master Molder(SM) Certification Series - either as a primer or as follow-up training.

- Introduction

- Metric and Imperial Units

- Time and Temperature

- Speed, Length and Distance

- Area, Volume and Flow

- Weight, Mass and Force

- Mass Flow Rate

- Pressure

- Units: Conversions

- Units: Multiplying and Dividing

- Units: Adding and Subtracting

- Percentages

- Averages

- Calculations: Plastic Pressure

- Calculations: Part Shrinkage

- Calculations: Tolerances

- Conclusion

- Identify whole numbers and know how negative numbers are used.

- Identify the common units used within the plastics industry.

- Know how time is measured and the two systems used for temperature.

- Understand how speed and length are measured and expressed.

- Identify the basic formulas used to calculate area, volume and flow.

- Identify how weight, mass and force are expressed in Metric and Imperial units.

- Understand how the consumption of material is rated and expressed.

- Know how pressure is measured for polymer, air, hydraulic fluid, or water

- Know how to transfer a unit from one measurement system to another.

- Identify how units are combined or cancelled out when multiplying or dividing.

- Know how to treat units when adding or subtracting.

- Know how to represent a number as a fraction of one hundred.

- Know how to determine the average, or mean, of a group of numbers.

- Know how to convert the hydraulic pressure to the plastic pressure.

- Understand that shrinkage can be expressed as a ratio or a percentage.

- Identify a target dimension and its acceptable upper and lower tolerances.

© Mastery Technologies, Inc.