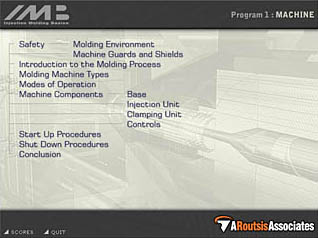

Plastics: Injection Molding Basics 1: Machine

- Product ID

- arbs01us

- Training Time ?

- 55 to 110 minutes

- Language(s)

- English

- Video Format

- Standard Definition

- Required Plugins

- MasteryNet Player

- Lesson Interactions

- 57

- Quiz Questions

- 43

The first of a three part training series, this course provides a general understanding of the injection molding machine, using 3D animation to demonstrate the inner workings of the machine to easily convey otherwise complex concepts. Specific content cites important safety precautions for working around injection molding machines, gives an introduction to the injection molding process, introduces machine types and the different modes of operation, discusses the components of the injection molding machine and their respective functions, and provides general procedures for starting up and shutting down a molding machine.

![]() This course is in the Advantage™ format, to read about Advantage™ features click here.

This course is in the Advantage™ format, to read about Advantage™ features click here.

- Install on any SCORM LMS

- Rich multimedia presentation with interactions and quiz

- Print certificate and wallet card

- You have 30 days to complete the course

Anyone working or planning to work with injection molding within the plastics industry. While the basic injection molding series is ideal for new hires, it also serves as an excellent refresher course for anyone involved in plastics processing.

- Safety: Molding Environment

- Safety: Machine Guards and Shields

- Introduction to the Molding Process

- Molding Machine Types

- Modes of Operation

- Machine Components: Base

- Machine Components: Injection Unit

- Machine Components: Clamping Unit

- Machine Components: Controls

- Start Up Procedures

- Shut Down Procedures

-

Fully understood all regulations before working near molding equipment.

- Know that each state, region, or country determines precautions.

- Be aware of all emergency exits, eyewash stations and first aid kits

- Always ensure that the area around the molding machine is clean.

- Know where forklifts and other moving equipment travel.

-

Know the different safety features of an injection molding machine.

- Agree that molding machines use extraordinary speeds, pressures and temps.

- Identify extreme forces used to open and close the injection mold.

- Explain Polymers temperatures used in injection molding.

-

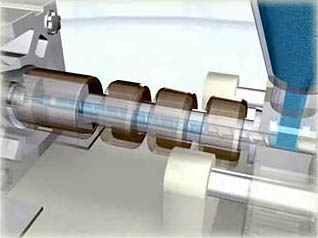

Know how plastic pellets are transformed into molded parts.

- Choose the proper process of pellets being fed into the hopper.

- Identify the purpose of a screw conveying and melting the pellets within the barrel.

-

Know that there are different types of molding machines.

- List molding machines power as either hydraulic or electric.

- Explain how a machine is rated.

-

Understand the injection molding machine's three modes of operation.

- List the three modes of operation; manual, semi-automatic, and automatic.

- Explain how parts are molded when using the automatic mode.

-

Identify the base of an injection molding machine.

- Identify what the base supports.

- State the use of the base of electric machines.

- Select the proper base size for larger molding machines.

-

Identify the injection unit of a molding machine.

- Name the injection unit's largest component.

- Locate where sensors are mounted.

-

Identify the clamping unit of an injection molding machine.

- Explain the mounting of the two mold halves.

- Identify the name used to describe the right platen.

-

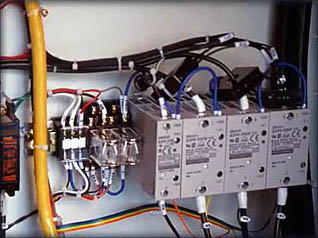

Identify the use of the control panel of an injection molding machine.

- Agree that the control panel is used to manage virtually every function of the machine.

- Recall that the operator interfaces with an LCD screen to make adjustments.

- List linear potentiometers and optical encoders used with modern machines.

-

Know the general start up procedures that apply to most molding machines.

- Agree to reviewing your plant's procedures with a supevisor.

- Select the length of time typically needed for a 'cold start'.

- List the first in the machine process.

-

Know general shut down procedures for a molding machine.

- Recall the need to stop the material from entering the feed throat.

- Agree to turn off barrel heaters, temp controllers, and all pumps and motors.

© Mastery Technologies, Inc.