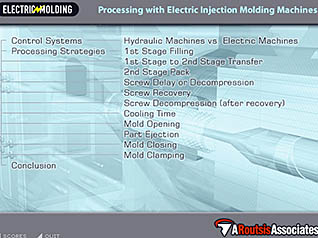

Processing with Electric Molding Machines

- Product ID

- arpseim2

- Training Time ?

- 62 to 124 minutes

- Language(s)

- English

- Video Format

- Standard Definition

- Required Plugins

- MasteryNet Player

- Lesson Interactions

- 64

- Quiz Questions

- 49

This training provides learners with in-depth processing information for making appropriate and cost-effective decisions when working with electric injection molding machines.

Using standard industry terms and practices, with an emphasis on safety, this two-part training series will enhance the knowledge base of all production personnel involved with electric injection molding machines.

Processing with electric injection molding machines will identify several differences between hydraulic molding machines and all electric molding machines. Users will also learn how to optimize a given process running on an electric molding machine so they can take advantage of those differences. Topics include closed-loop process controls, hydraulic verses electric machine controls, and optimization strategies for various processes.

![]() This course is in the Advantage™ format, to read about Advantage™ features click here.

This course is in the Advantage™ format, to read about Advantage™ features click here.

- Rich multimedia presentation with interactions and quiz

- Print certificate and wallet card

- You have 30 days to complete the course

Anyone working with electric molding machines.

- Control Systems

- Processing: First Stage Filling

- Processing: First to Second Stage Transfer

- Processing: Second Stage Pack

- Processing: Screw Delay or Decompression

- Processing: Screw Recovery

- Processing: Screw Decompression (after rec.)

- Processing: Cooling Time

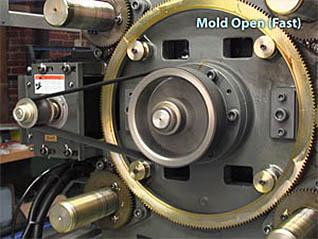

- Processing: Mold Opening

- Processing: Part Ejection

- Processing: Mold Closing

- Processing: Mold Clamping

- Differentiate hydrualic and electric machines.

- Avoid using a pressure-limited process.

- Know when and how to properly transfer from first to second stage.

- Determine appropriate second stage time.

- Use the different ways to relieve pressure in front of the screw.

- Determine the optimal feed zone temperature for a process.

- Identify the ways to relieve pressure on the check ring.

- Optimize cooling time on an electric molding machine.

- Identify the different speeds used during mold opening.

- Use the proper practices to remove parts from an electric machine.

- Understand how different speeds are used during mold closing.

- Optimize mold clamping on an electric molding machine.

© Mastery Technologies, Inc.