Plastics: Single Screw Extrusion: Quality

- Product ID

- arssequa

- Training Time ?

- 33 to 66 minutes

- Language(s)

- English

- Video Format

- Standard Definition

- Required Plugins

- MasteryNet Player

- Lesson Interactions

- 35

- Quiz Questions

- 26

Single Screw Extrusion: Quality is the sixth training course of the Single Screw Extrusion Series. These eight programs are designed to train anyone working in a production environment. Using 3D animation and actual production footage to demonstrate complex concepts, important safety precautions are stressed throughout the training series.

"Single Screw Extrusion: Quality" defines quality and its importance to the success of extrusion operations, explains the concepts of quality assurance vs. quality control, covers the form, fit, and functionality of the extruded product, compares and constrasts critical vs. non-critical extrudate defects, and stresses the importance of meeting the customer's needs.

Tailored for Single Screw Extruders, these training courses provide specific information for all extruders from blown film to profile extrusion. Whether you use single stage or vented extruders, the information will relate to the equipment, materials, and processes operating at your facility.

This training series with help teach any employee the concepts relating to the machine, material, process, quality, startup, shutdown, problem solving, material handling as well as the correct terminology associated with Single Screw Extrusion.

![]() This course is in the Advantage™ format, to read about Advantage™ features click here.

This course is in the Advantage™ format, to read about Advantage™ features click here.

- Rich multimedia presentation with interactions and quiz

- Print certificate and wallet card

- You have 30 days to complete the course

For all personnel involved in Single Screw Extrusion.

- Quality Assurance

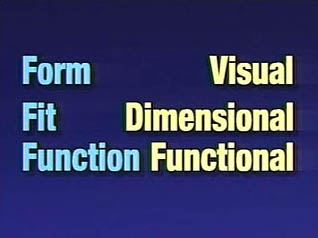

- Form, Fit and Function

- Measuring

- Defects: Critical vs. Non-Critical

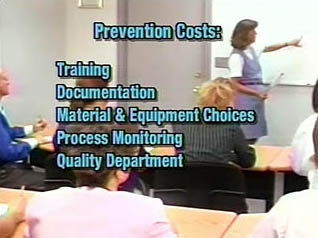

- The Cost of Quality

- Statistical Process Control

- Know what Quality means, which is meeting the customer's requirements.

- Identify which defects are related to either; Form, Fit and Function.

- Know how to properly measure extruded product.

- Identify which defects are critical and which ones are non-critical.

- Know what costs are attributed to adhering product quality.

- Know how numerical data is collected, analyzed, and interpreted.

© Mastery Technologies, Inc.