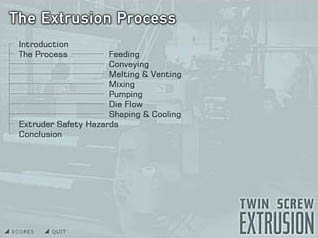

Plastics: Twin Screw Extrusion: The Extrusion Process

- Product ID

- artsepro

- Training Time ?

- 44 to 88 minutes

- Language(s)

- English

- Video Format

- Standard Definition

- Required Plugins

- MasteryNet Player

- Lesson Interactions

- 43

- Quiz Questions

- 32

"The Extrusion Process" explains the mechanics of Twin Screw material feeding and conveying, details the melting processes, describes the commonly used types of mixing systems, covers venting and pumping, die flow, shaping, and cooling. The content also highlights extruder safety hazards.

Tailored for Twin Screw Extruders, this training course provides specific information for profile, pipe, or compounding extruders. Whether you use a co-rotating or counter rotating extruder, the information will relate to the equipment, materials, and processes operating at your facility.

This training helps teach any employee the concepts relating to the machine, material, process, quality, startup, shutdown, problem solving, material handling as well as the correct terminology associated with Twin Screw Extrusion.

![]() This course is in the Advantage™ format, to read about Advantage™ features click here.

This course is in the Advantage™ format, to read about Advantage™ features click here.

- Rich multimedia presentation with interactions and quiz

- Print certificate and wallet card

- You have 30 days to complete the course

For all personnel involved in Twin Screw Extrusion.

- Feeding

- Conveying

- Melting & Venting

- Mixing

- Pumping

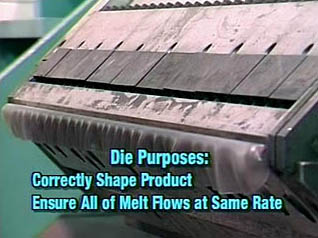

- Die Flow

- Shaping & Cooling

- Extruder Safety Hazards

- Identify different feed problems and their causes.

- Know how material is conveyed by a twin screw extruder.

- Know when material starts melting and how venting works.

- Know how material must be mixed before entering the die.

- Know how material is pumped to the die using drag flow.

- Identify the different parameters and additives that affect die flow.

- Know how extruded product is both shaped and cooled.

- Identify the different hazards that an extruder poses.

© Mastery Technologies, Inc.